Administration of Estates Act, 1965

Administration of Estates Act, 1965

R 385

National Regulator for Compulsory Specifications Act, 2008 (Act No. 5 of 2008)NoticesCompulsory Specification for Energy Efficiency and Functional Performance Requirements of General Service Lamps (GSLs) - VC 9107Annexure B - Endurance Test Method and Sequence |

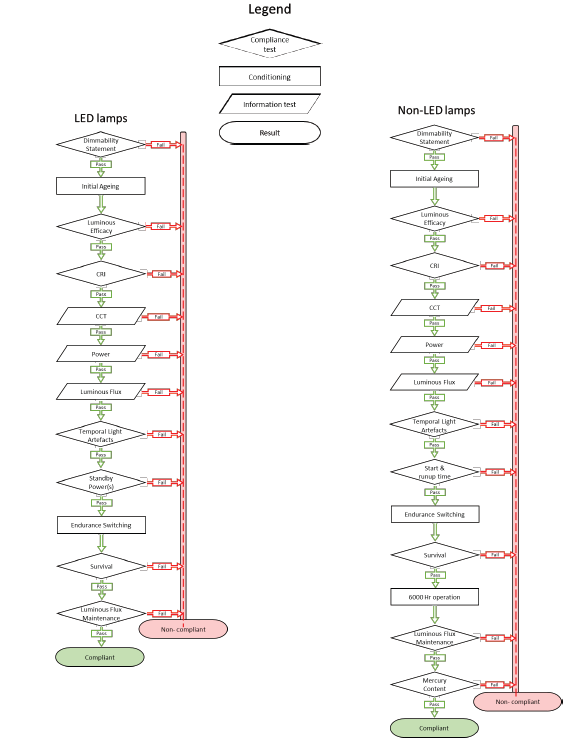

Light sources shall undergo endurance testing to verify their luminous flux maintenance factor and survival factor. This endurance testing consists of the test method outlined below for LED and OLED light sources:

| B1 | AMBIENT CONDITIONS AND TEST SETUP |

| B1.1 | The switching cycles are to be conducted in a room with an ambient temperature of 25°C ±10°C and an average air velocity of less than 0.2 m/s. |

| B1.2 | The switching cycles on the sample shall be conducted in free air in a vertical base-up position. However, if a supplier has declared the light source is suitable for use in a specific orientation only, then the sample shall be mounted in that orientation. B1.3 The applied voltage during the switching cycles shall have a tolerance within 2%. The total harmonic content of the supply voltage shall not exceed 3%. Standards provide guidance on the supply voltage source. |

| B2 | PROVISIONAL ENDURANCE TEST METHOD |

| B2.1 | Initial flux measurement: measure the luminous flux of the light source prior to starting the endurance test switching cycle. |

| B2.2 | Switching cycles: operate the light source for 1200 cycles of repeated, continuous switching cycles without interruption. One complete switching cycle consists of 150 minutes of the light source switched ON at full power followed by 30 minutes of the light source switched OFF. The hours of operation recorded (i.e., 3000 hours) include only the periods of the switching cycle when the light source was switched ON, i.e. the total test time is 3600 hours. |

| B3.3 | Final flux measurement: at the end of the 1200 switching cycles, note if any lamps have failed (see ‘Survival Factor’ requirements in Section 4.3 Table 5) and measure the luminous flux of the light sources that have not failed. |

| B4.4 | For each of the units in the sample which have not failed, divide the measured final flux by the measured initial flux. The arithmetical mean of the resulting values of all the units that did not fail provides the determined value for the luminous flux maintenance factor XLMF%. |