National Nuclear Regulator Act, 1999

National Nuclear Regulator Act, 1999

R 385

Occupational Health and Safety Act, 1993 (Act No. 85 of 1993)Code of PracticeNational Code of Practice for Electrical Machinery in Hazardous LocationsRegulatory requirements for explosion-protected apparatusAnnexesAnnex C (informative) : Marking of electrical apparatus for use in explosive atmospheres |

Annex C

(informative)

Marking of electrical apparatus for use in explosive atmospheres

| C.1 | General |

| C.1.1 | Certain compulsory information (because it is required to ensure safety) shall be marked on explosion-protected equipment in a safe,legible and durable manner (see SANS 60598-1 for marking guidance). The marking information required in accordance with national and similar standards includes |

| (a) | the name of the equipment manufacturer, |

| (b) | a description of the equipment (make and model (or frame size)), |

| (c) | the unique identification (serial) number of the equipment, |

| (d) | the electrical input and output data of the equipment, |

| (e) | the explosion-protection ratings, |

| (f) | conditions associated with certification, and |

| (g) | the ATL and IA certificate number. |

| C.1.2 | Reduced marking for small and very small equipment is covered by the IEC and CENELEC standards. |

In this annex, information and examples are given of marking of explosion-protected equipment.

NOTE As there are currently major developments in IEC explosion-protection standards and therefore by implication in South African National Standards, the reader is encouraged to use only the latest edition of this recommended practice together with SANS 10108.

| C.2 | Marking of explosion-protection ratings |

| C.2.1 | General |

Standards approved (or which have been approved in the past) for certification of explosion-protected apparatus used in South Africa can be Grouped according to their approach to the marking of explosion-protection ratings, as given in C.2.2 and C.2.3.

| C.2.2 | IEC, CENELEC and related South African National Standards |

| C.2.2.1 | As part of the drive towards global standardization, cooperation between the IEC and CENELEC requires the corresponding technical committees to consider each other's standards for mutual acceptance. As a result, several of these standards are identical or closely related. |

| C.2.2.2 | The IEC and CENELEC standards (the latter applicable under the ATEX Directive) for apparatus used in explosive gases and vapours atmospheres call for the following marking: |

|

(E)Ex |

d |

IIB |

T3 |

|

Indicative of explosion-protected apparatus built in accordance with IEC |

Type of protection: Flameproof apparatus (CENELEC) standards |

Equipment Group gas |

Temperature class |

NOTE The CENELEC standards require additional marking,refer to C.2.2.4.

The current, unified marking system specified by IEC requires that the equipment protection level (EPL) is added at the end of the above marking (see C.5 for examples).

| C.2.2.3 | The certificate number could be followed by one of the following identification letters: |

| X: | The applicable specific conditions at the letter-symbol X should be ascertained from the contents of the certificate. |

| U: | An incomplete piece of explosion-protected apparatus or component (for example, unequipped enclosures, lamp holders, contact blocks, terminals, plugs, reducers, and impregnation materials). |

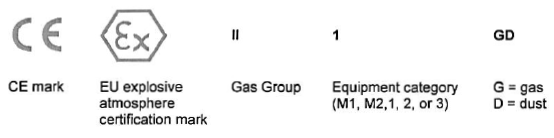

| C.2.2.4 | The ATEX Directive requires marking in addition to the marking given in C.2.2.2 and C.2.2.3; marking that identifies the category of equipment required (the zone in IEC terminology). |

| C.2.3 | North American standards |

| C.2.3.1 | General |

| C.2.3.1.1 | Historically, explosion-protected apparatus certified to selected FM and UL standards (USA) and CSA standards has been accepted in South Africa. |

This is no longer the case,but marking information is included as an aid to technical staff dealing with operational equipment.

| C.2.3.1.2 | In the United States of America, FM, UL and ISA standards have also been accepted as American National Standards Institute (ANSI) standards. Although the North American standards for explosion protection differ from the IEC and CENELEC standards, North-American products with certification to IEC and CENELEC standards for explosion protection are on the increase, as is the acceptability of IEC standards . |

| C.2.3.2 | Underwriters' Laboratories (UL) and Canadian Standards Association (CSA) |

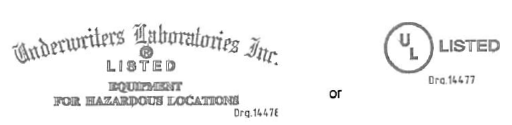

In the immediate vicinity of the certification mark, a statement appears that the specified equipment is for use in hazardous locations. The Groups of hazardous materials are given by the statement: "class I, Group A, B, C or D" (or a combination of these), and "class II, Group E, F or G" (or a combination of these). The gases and vapours appropriate to class I, Groups A, B, C and D and the dusts appropriate to class II, Groups E, F and G are given in NFPA 70.

A separate statement as to whether the equipment is intrinsically safe or explosion-proof (flameproof) might appear, but dust-ignition-proofing (dust-ignition-protection) is always indicated by a coded reference to the types of material for which the equipment has been certified.

| C.2.3.3 | Factory Mutual Research Cooperation (FMRC) |

Equipment is marked, in the immediate vicinity of the FM mark,indicating whether it is intrinsically safe or explosion-proof (flameproof) for class I, divisions 1 and 2 (zone 1 and zone 2) locations or non-incendive (non-sparking) for zone 2 locations only. The gases and vapours for which the electrical apparatus is suitable are given by the statement, "class I, Groups A, B, C or D" (or a combination of these),as for the UL and CSA.

| C.3 | Additional marking for specific purposes |

Additional marking may include

| (a) | a warning marking, for example,"WARNING - DO NOT OPEN WHEN ENERGIZED", or |

| (b) | a specific condition of use (in which case the "X" suffix to the certificate number is not required, (see C.2.2.3)), for example, "STATIC HAZARD - WIPE WITH A DAMP CLOTH ONLY". |

| C.4 | Apparatus group and temperature class conventions |

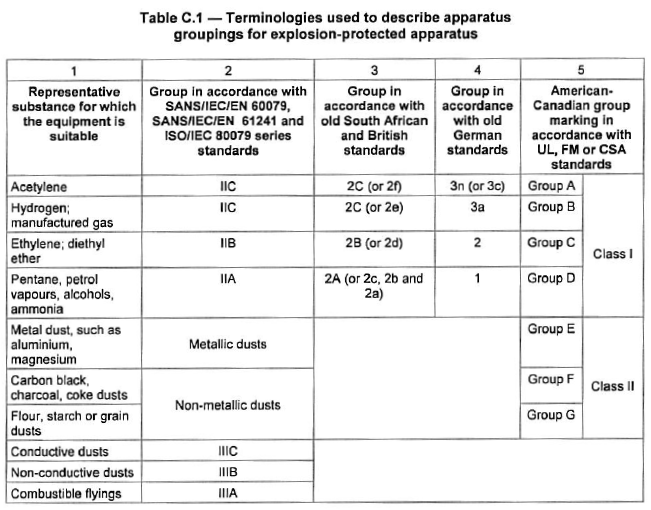

| C.4.1 | Table C.1 gives a simplified comparison of terminologies used to describe the different apparatus groupings applicable to gases, vapours and dusts, in respect of explosion-protected apparatus. |

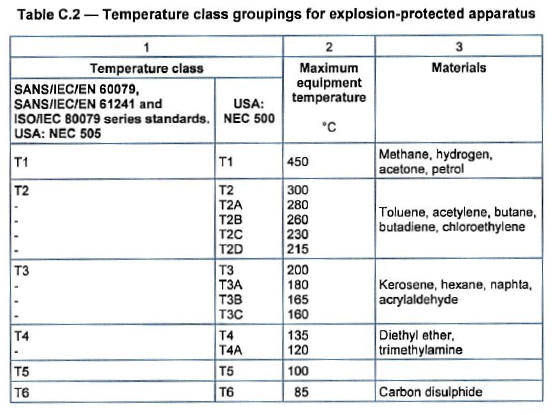

| C.4.2 | Table C.2 gives simplified comparison of the different equipment temperature classes applicable to gases and vapours, in respect of explosion-protected apparatus. |

| C.5 | Examples of markings |

| C.5.1 | Examples of the compulsory marking of explosion-protected electrical apparatus in accordance with the IEC unified marking system are given in C.5.2 to C.5.13. |

NOTE 1 These examples do not include the marking normally required by the general standards for construction of electrical apparatus (for example, electrical parameters); however, said marking forms part of the compulsory marking of explosion-protected apparatus.

NOTE 2 Practical considerations might restrict or preclude the use of it al c characters or of subscripts and a simplified presentation may be used, for example Uo rather than Uo.

| C.5.2 | Examples of marking for electrical equipment with the type of protection flameproof enclosure "d" (EPL Ma or EPL Mb) for use in mines susceptible to firedamp: |

|

Bedelle S.A |

alternate Ex db I 150 °C |

|

Type A B 5 |

|

|

Ex d I 150 °C Ma |

|

|

No. 325 |

|

|

ABC 02. 1234 |

|

|

Bedelle S.A |

alternate Ex db I 150 °C |

|

Type A B 5 |

|

|

Ex d I 150 °C Ma |

|

|

No. 325 |

|

|

ABC 02. 1234 |

| C.5.3 | An example of marking for Ex component, with the type of protection flameproof enclosure "d" (EPL Gb) with intrinsically safe "ia" (EPL Ga) output circuit, for explosive gas atmospheres other than in mines susceptible to firedamp, gas of subdivision C, manufactured by H. Ridstone and Co. Ltd: |

|

Type KW 369: |

alternate Ex db [ia] IIC |

|

Ex d [ia Ga] IIC Gb |

|

|

DEF 02 0536 U |

|

|

HR |

| C.5.4 | An example of marking for electrical equipment, utilizing types of protection increased safety "e" (EPL Gb) and pressurized enclosure "px" (EPL Gb), maximum surface temperature of 125 °C, for explosive gas atmospheres other than mines susceptible to firedamp, with gas of ignition temperature greater than 125 °C, and with specific conditions of use indicated in the certificate: |

|

H. Atherington Ltd |

alternate Ex eb pxb IIC 125 oC (T4) |

|

Type 250 JG 1 |

|

|

Ex e px IIC 125 oC (T4) Gb |

|

|

No. 56732 |

|

|

GHI 02.0076 X |

| C.5.5 | An example of marking for electrical equipment, utilizing types of protection flameproof enclosure "d" (EPL Mb and Gb) and increased safety "e" (EPL Mb and Gb) for use in mines susceptible to firedamp and explosive gas atmospheres other than mines susceptible to firedamp with gas of subdivision B and ignition temperature greater than 135 °C: |

|

A.R. Achutz A.G. |

alternate Ex db eb I T4 oC alternate Ex db eb IIB T4 |

|

Type 5 CD |

|

|

Ex d e I T4 Mb |

|

|

Ex d e IIB T4 Gb |

|

|

No. 5634 |

|

|

JKL 02.052 |

| C.5.6 | An example of marking for electrical equipment with type of protection flameproof enclosure "d" (EPL Gb) for explosive gas atmospheres other than mines susceptible to firedamp on the basis of ammonia gas only: |

|

Wokaitert Sarl |

alternate Ex db II (NH3) |

|

Type NT 3 |

|

|

Ex d II (NH3) Gb |

|

|

No. 6549 |

|

|

MNO 02.31 |

| C.5.7 | An example of marking for electrical equipment with type of protection encapsulation "ma" (EPL Da) for explosive dust atmospheres containing conductive dusts of Group IIIC with a maximum surface temperature of less than 120 °C: |

|

ABC Company |

alternate Ex ma IIIC T120 oC |

|

Type RST |

|

|

Serial No. 123456 |

|

|

Ex ma IIIC T120 °C Da |

|

|

IP68 |

|

|

N.A. 01.9999 |

| C.5.8 | An example of marking for electrical equipment with type of protection "ia" (EPL Da) for explosive dust atmospheres containing conductive dusts of Group IIIC with a maximum surface temperature of less than 120 °C: |

|

ABC Company |

alternate Ex ia IIIC T120 oC |

|

Type XYZ |

|

|

Serial No. 123456 |

|

|

Ex ia IIIC T120 °C Da |

|

|

IP20 |

|

|

N.A. 01.9999 |

| C.5.9 | An example of marking for electrical equipment with type of protection "p" (EPL Db) for explosive dust atmospheres containing conductive dusts of Group IIIC with a maximum surface temperature of less than 120 °C: |

|

ABC Company |

alternate Ex pb IIIC T120 oC |

|

Type KLM |

|

|

Serial No. 123456 |

|

|

Ex p IIIC T120 °C Db |

|

|

IP65 |

|

|

N.A. 01.9999 |

| C.5.10 | Electrical equipment with type of protection "t" (EPL Db) for explosive dust atmospheres containing conductive dusts of Group IIIC with a maximum surface temperature of less than 225°C and less than 320°C when tested with a 500 mm dust layer: |

|

ABC Company |

alternate Ex tb IIIC T225 °C T500 320°C |

|

Type RST |

|

|

Serial No. 987654 |

|

|

Ex t IIIC T225 °C T500 320°C Db |

|

|

IP65 |

|

|

N.A. 02.1111 |

| C.5.11 | An example of marking for electrical equipment with type of protection "t'' (EPL Db) for explosive dust atmospheres containing conductive dusts of Group IIIC with a maximum surface temperature of less than 175 °C with an extended ambient temperature range of -40 °C to +120 °C: |

|

ABC Company |

alternate Ex tb IIIC T175 oC |

|

Type RST |

|

|

Serial No. 987654 |

|

|

Ex t IIIC T175 °C Db |

|

|

IP65 |

|

|

-40 °C ≤ Tamb ≤ 120°C |

|

|

N.A. 02.1111 |

| C.5.12 | An example of marking for electrical equipment with type of protection encapsulation "ma" (EPL Ga) for explosive gas atmospheres of Group IIC with a maximum surface temperature of less than 135 °C and with type of protection encapsulation "ma" (EPL Da) for explosive dust atmospheres containing conductive dusts of Group IIIC with a maximum surface temperature of less than 120°C, and for which a single certificate has been prepared: |

|

ABC Company |

alternate Ex ma IIC T4 alternate Ext ma IIIC T120 °C |

|

Type RST |

|

|

Serial No. 123456 |

|

|

Ex ma IIC T4 Ga |

|

|

Ext ma IIIC T120 °C Da |

|

|

IP67 |

|

|

N.A. 01.9999 |

| C.5.13 | An example of marking for electrical equipment with type of protection encapsulation "ma" (EPL Ga) for explosive gas atmospheres of Group IIC with a maximum surface temperature of less than 135 °C and with type of protection encapsulation "ma" (EPL Da) for explosive dust atmospheres containing conductive dusts of Group IIIC with a maximum surface temperature of less than 120°C, and for which two independent certificates have been prepared: |

|

ABC Company |

alternate Ex ma IIC T4 alternate Ext ma IIIC T120 °C |

|

Type RST |

|

|

Serial No. 123456 |

|

|

Ex ma IIC T4 Ga |

|

|

N.A. 01.1111 |

|

|

Ext ma IIIC T120 °C Da |

|

|

IP54 |

|

|

N.B. 01.9999 |

| C.6 | Approved certification bodies and their certification marks |

| C.6.1 | Approved South African certification marks |

Most approved certification bodies use a certification mark that indicates unambiguously, or in conjunction with other symbols, that the apparatus is certified as explosion protected. The following certification marks are commonly found on apparatus used in South Africa:

| C.6.2 | Foreign certification marks |

The following marks do not indicate acceptable certification for new equipment, but may be used as the basis for issuing an IA certificate by an ATL for equipment in use:

| (a) | British Approvals Service for Electrical Equipment in Flammable Atmospheres (BASEEFA), or Ministry of Power, or Ministry of Technology, or Department of Trade and Industry, United Kingdom |

NOTE The BASEEFA marks shown below were issued at various times during the existence of this organization. The organization has since been privatised. The current BASEEFA 2001 (Pty) Ltd is one of the EC Notified Bodies and uses the marking system referred to in C.6.2(f). Only second-hand apparatus will therefore carry this mark.

| (b) | Physikalisch-Technische Bundesanstalt (PTB) or Bergbau Versuchsstrecke (BVS), Germany |

NOTE This mark organization has since been appointed as one of the EC Notified Bodies and uses the marking system referred to in C.6.2(f). Only second-hand apparatus will therefore carry this mark.

| (c) | Underwriters' Laboratories (UL), USA |

| (d) | Factory Mutual Research Corporation (FM), USA |

| (e) | Canadian Standards Association (CSA) |

| (f) | Certification mark under the ATEX Directive (European Council Directive 94/9/EC) for equipment certified by a Notified Body |

NOTE The (abbreviated) name of the Notified Body is displayed as part of the certification number.

| (g) | Certification mark under the IECEx Scheme |

| C.7 | Unmarked electrical apparatus |

In the case of electrical apparatus that is unmarked, or where the marking is incomplete or there is doubtful applicability to the particular hazard, it should not be used and it should either be submitted for testing or certification (or both), or its use should be immediately discontinued.